Understanding Precision Machining in Malaysia

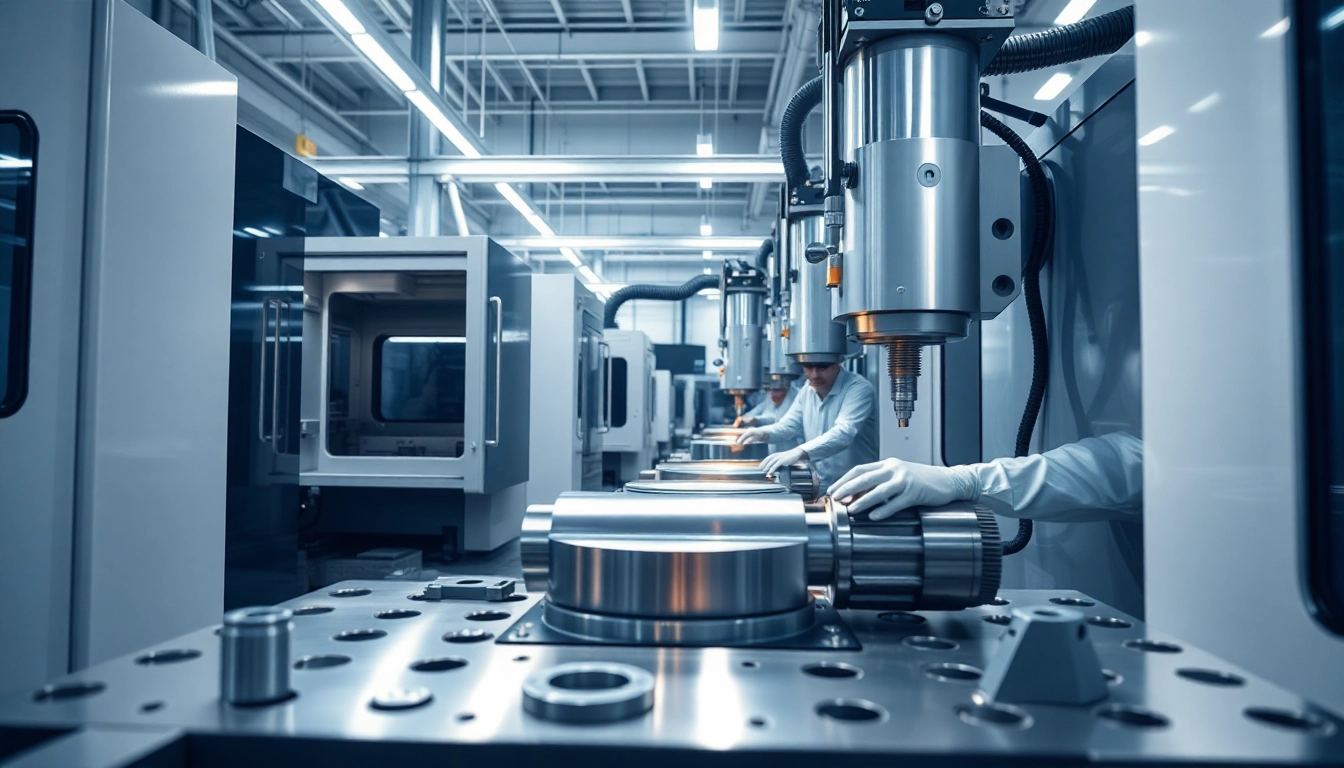

Malaysia is rapidly gaining recognition as a hub for precision machining, driven by a growing demand for high-precision components across various industries, including aerospace, automotive, and electronics. Precision machining is a sophisticated manufacturing process that utilizes advanced technology to achieve exceptional levels of accuracy and consistency. In this article, we will dive deep into the nuances of precision machining in Malaysia, exploring its significance, the technologies involved, and the challenges faced by manufacturers.

When exploring options, precision machining malaysia offers insights not just for manufacturers, but also for businesses looking to source high-quality components. Understanding the local landscape is crucial for making informed decisions about partnerships and investments in this sector.

What is Precision Machining?

Precision machining involves the use of computer-controlled equipment to manufacture parts and components with tight tolerances. This method employs various techniques such as turning, milling, grinding, and electrical discharge machining (EDM) to produce intricately designed products from metals, plastics, and composites. The key to precision machining lies in its ability to consistently produce parts that meet specific dimensional specifications, which is essential for high-performance applications.

The Importance of Precision Machining in Modern Manufacturing

In today’s competitive manufacturing landscape, precision machining holds a pivotal role. Its significance can be encapsulated in several key areas:

- Quality Assurance: Precision machining ensures that components are made to exact specifications, minimizing defects and rework costs.

- Cost Efficiency: By streamlining production processes, precision machining reduces material waste and labor costs associated with less accurate manufacturing methods.

- Customization: This machining technique allows manufacturers to create customized components tailored to specific requirements, enhancing product offerings in various industries.

Key Technologies in Precision Machining Malaysia

Malaysia’s precision machining sector benefits from several advanced technologies that enhance production capabilities:

- CNC Machining: Computer Numerical Control (CNC) machinery automates the manufacturing process, allowing for precise and repeatable cuts.

- 3D Printing: Additive manufacturing techniques enable rapid prototyping and the production of complex geometries that are difficult to achieve with traditional machining.

- Laser Cutting: This technology provides high precision in cutting and engraving materials, widely used in industries such as automotive and consumer electronics.

Challenges in the Precision Machining Industry

Common Misconceptions about Precision Machining

Despite its significance, several misconceptions surround precision machining:

- High Cost: Many believe that precision machining is inherently expensive; however, the savings from reduced waste and enhanced efficiency often outweigh initial costs.

- Limited to Specific Industries: While it is true that industries like aerospace and automotive heavily rely on precision machining, its applications extend to medical, electronics, and even consumer goods.

Identifying and Overcoming Industry Challenges

The precision machining industry in Malaysia faces challenges such as labor shortages, supply chain disruptions, and the need for continuous investment in technology. Companies must develop strategies to attract skilled workers, streamline their operations, and remain adaptable to industry changes.

Case Studies: Lessons from Failed Projects

Learning from failures is crucial in any industry. For instance, a local precision machining firm faced significant setbacks due to inadequate quality checks, leading to a high return rate of defective products. By implementing rigorous quality control procedures and investing in employee training, the company was able to turn its performance around, significantly improving its operational efficiency and customer satisfaction.

Best Practices for Precision Machining

Quality Control Measures in Precision Machining Malaysia

Ensuring the quality of machined parts is paramount. Best practices include:

- Regular Equipment Calibration: Keeping machines calibrated prevents inaccuracies that can lead to defective products.

- Statistical Process Control (SPC): Utilizing SPC techniques helps monitor production processes and detect variations before they result in defects.

Implementing Lean Manufacturing Techniques

Lean manufacturing focuses on minimizing waste and maximizing productivity. In precision machining, this can be achieved by:

- Streamlining Workflow: Assessing and redesigning workflows to eliminate non-value-adding steps.

- Just-in-Time Production: Producing components only as needed to reduce inventory costs and improve cash flow.

Investing in Advanced Technology and Equipment

To stay competitive, manufacturers must invest in the latest technologies such as:

- Automation: Robotic systems can significantly enhance efficiency and reduce labor costs.

- Advanced Software: Utilizing CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software helps optimize design and production processes.

Future Trends in Precision Machining (2025 and Beyond)

Impact of Automation and AI in Precision Machining

Automation and artificial intelligence are set to revolutionize precision machining by enhancing precision and reducing the possibility of human error. Smart factories equipped with AI will analyze production data in real-time, facilitating better decision-making and process optimization.

Sustainability Practices in the Manufacturing Process

As environmental concerns continue to grow, sustainability in manufacturing is becoming more critical. Precision machining firms are exploring eco-friendly materials, recycling scrap metal, and adopting energy-efficient practices to minimize their carbon footprint.

Emerging Markets and Opportunities for Growth

The global demand for precision machining is expected to rise, particularly in emerging markets. Companies in Malaysia can leverage this trend by expanding their service offerings and exploring niche markets such as green technologies and electric vehicles.

Getting Started with Precision Machining in Malaysia

Choosing the Right Partner for Precision Machining Services

Selecting a manufacturing partner is crucial. Consider the following when making your choice:

- Experience: Look for a company with a proven track record in your industry.

- Technology: Assess if they utilize advanced techniques that align with your project needs.

Essential Skills for Precision Machining Professionals

As the industry evolves, so do the skills required. Key competencies include:

- Technical Expertise: Knowledge of machine operation and programming is essential.

- Problem-Solving Skills: The ability to troubleshoot issues swiftly can save time and costs.

Measuring Success: KPIs in Precision Machining Projects

Defining key performance indicators (KPIs) is paramount to gauge the success of precision machining initiatives. Important KPIs include:

- First-pass Yield: The percentage of products that meet quality standards without requiring rework.

- Production Cycle Time: The time taken from order to delivery, which impacts customer satisfaction and operational efficiency.